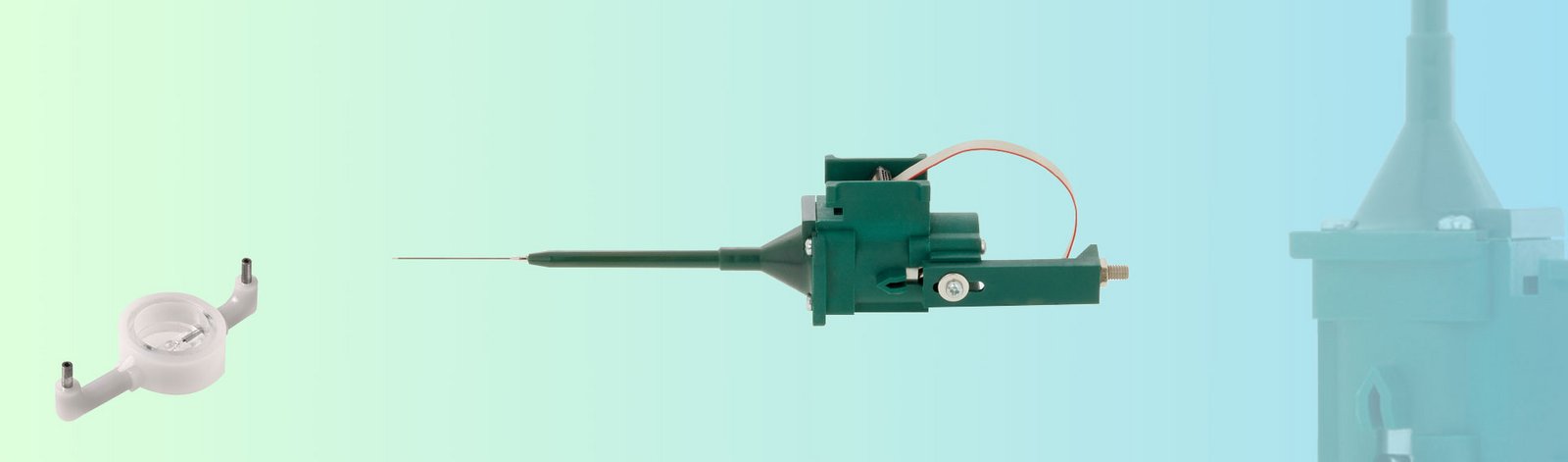

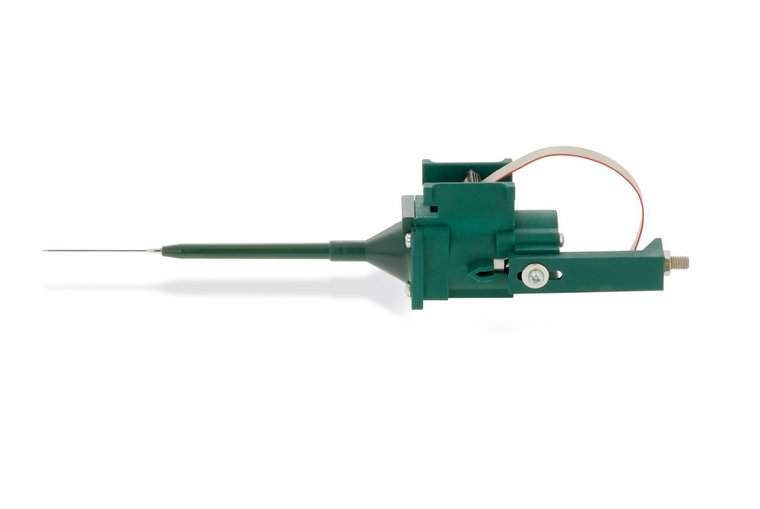

Analysenadeln

MÖLLER ist bereits seit mehreren Jahrzehnten Hersteller von hochwertigen Analysenadeln und Verbindungssystemen. Dabei arbeiten wir eng zusammen mit dem Kunden und entwickeln gemeinsam Lösungskonzepte. Hierbei kommt uns eine langjährige Expertise im Bereich der Metall- und Kunststoffverarbeitung zu Gute. Zu unseren Kunden zählen viele namenhafte Hersteller der Analytik-Branche.

Unsere Spezialitäten sind:

- Gerade einfache Nadeln

- Mehrkanal Nadeln

- Cap Piercing Nadeln

- Beheizte Nadeln

- Stahlnadeln mit integrierten PTFE/FEP Schlauch®

Verbindungssysteme und TorqFit Systeme

Dazu bieten wir komplette, auch beheizbare® technische Schlauchsysteme mit drei verschiedene Verbindungsmechanismen an:

- V1 einfach

- V2 totwasserarm®

- V3 totwasserfrei®

Mit unseren Verfahren ist es uns möglich, totwasserfreie Verbindungen sowohl zwischen Stahlnadel und Schlauchsystem als auch zwischen Kunststoffbauteilen und Schlauchsystemen zu schaffen.

Unsere TorqFit Serie wurde entwickelt um die Untergrenze der Drehmomente auf 12-15 Ncm zu limitieren. Dies dient dazu, dass es durch zu festes anziehen nicht zu Beschädigungen des Verbindungsbereiches kommt. Das Design und alle Parameter (Anzugsdrehmoment, Gewinde, Abmessungen, Material, etc.) können Ihren speziellen Bedürfnissen angepasst werden und sind individualisierbar.

Fertigungsverfahren

Die Wurzeln von Möller Medical liegen traditionell in der Feinwerktechnik. Dieser Einfluss ist bis heute zu spüren. Daher macht die Metall- und Kunststoffverarbeitung insbesondere durch direkte Umspritzung eine unsere Kernkompetenzen aus.

Wir bieten:

- Präzisionsspritzguss verschiedenster, auch autoklavierbarer, Kunststoffe (PEEK, PVDF, etc.) mit eigenem Formbau für das Einspritzen und Umspritzen von Komponenten

- bohren, schneiden, schweißen und beschriften mittels Laser

- Ultraschallschweißen und Sonderkonstruktionen in der Membranverbindungstechnik

- automatisiertes 3D frei-form Biegen

- eigener Werkzeugbau für höchste Kompetenz und Flexibilität für den Kunden

- Qualitätskontrolle mittels moderner Mess- und Analyseverfahren

Kontaktieren Sie uns